Technology and Innovation

To maintain Sunningdale’s technology

competitiveness, the Group continues

committing key resources of dedicated

engineers looking into new plastic

related technology and methods.

These were shared with customers

to explore better value proposition

for our customer’s products. There

has been encouraging signs and

feedback from our customers with

these engagement s wi th many

asking Sunningdale to present to

their R&D teams and initiation of

joint projects.

Early supplier involvement continues

to a key effort to be engaged at the

customers with their future products

to ensure Sunningdale is always

aware of latest trends and involved

with key customer’s opportunities.

This involvement includes working

directly with their engineers on design,

advising them on what features

are possible.

Last year Sunningdale completed

t h e X - r a y i n s pe c t i on me t hod

with SimTech (Singapore Institute

o f Manu f ac tur i ng Techno l ogy ) .

There are many more projects still

i n prog ress i nc l ud i ng po l yme r

material, printed electronics and

Microfluidics. There are also other

industry partners which the Group is

engaged with in different development

activities such as different types of

composite materials.

Sunningdale continues to be present

in key trade shows in Europe, to

ensure customers are aware of

our presence, capabilities and to

understand and keep up to date on

latest technology updates. In the

recent Medtech in Suntec City where

the key guest of honor scheduled a

stop at our booth.

Competitive

To ensure the long term interest of

the Group, management’s key priority

is to always remain profitable and

competitive. The General Managers

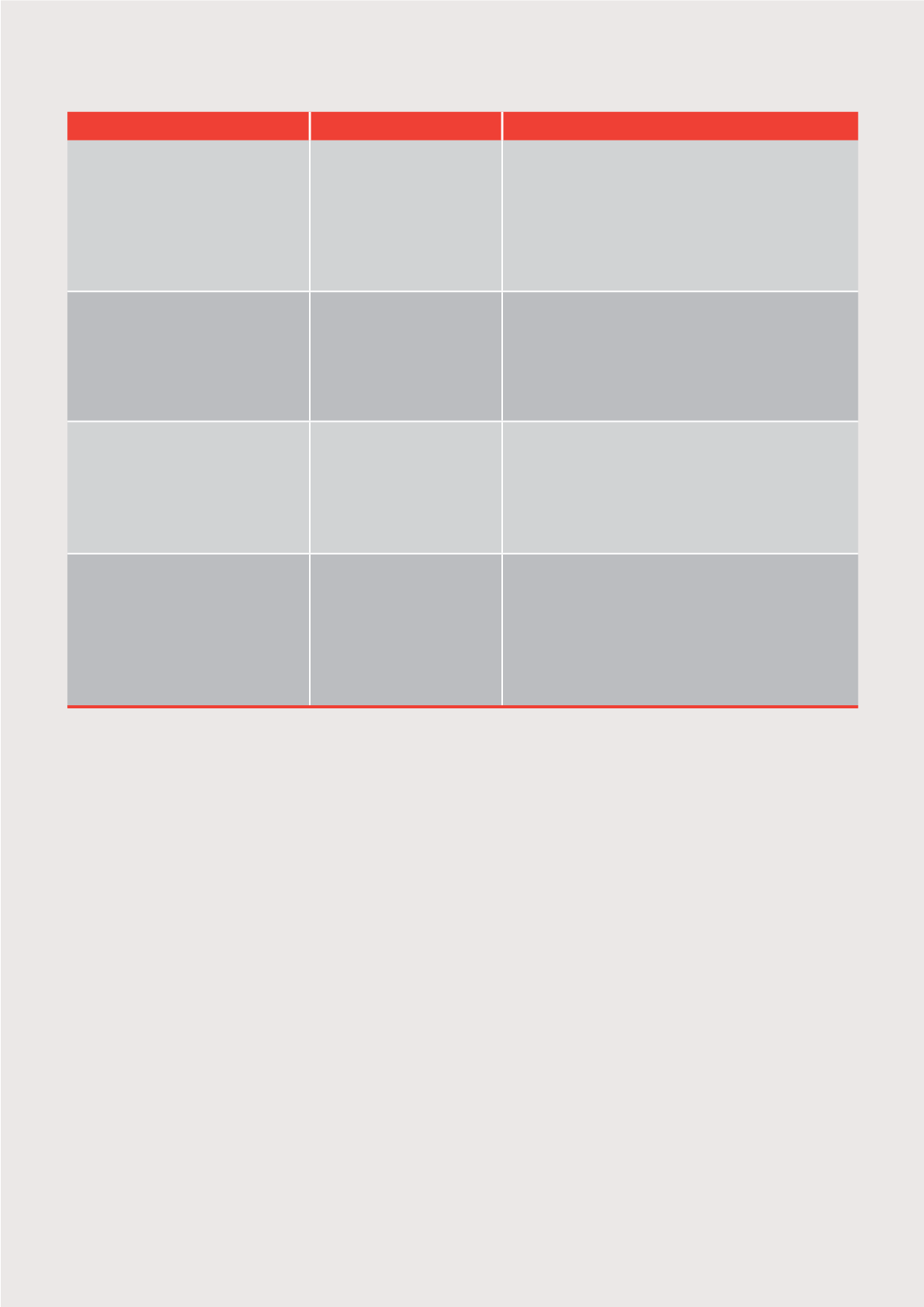

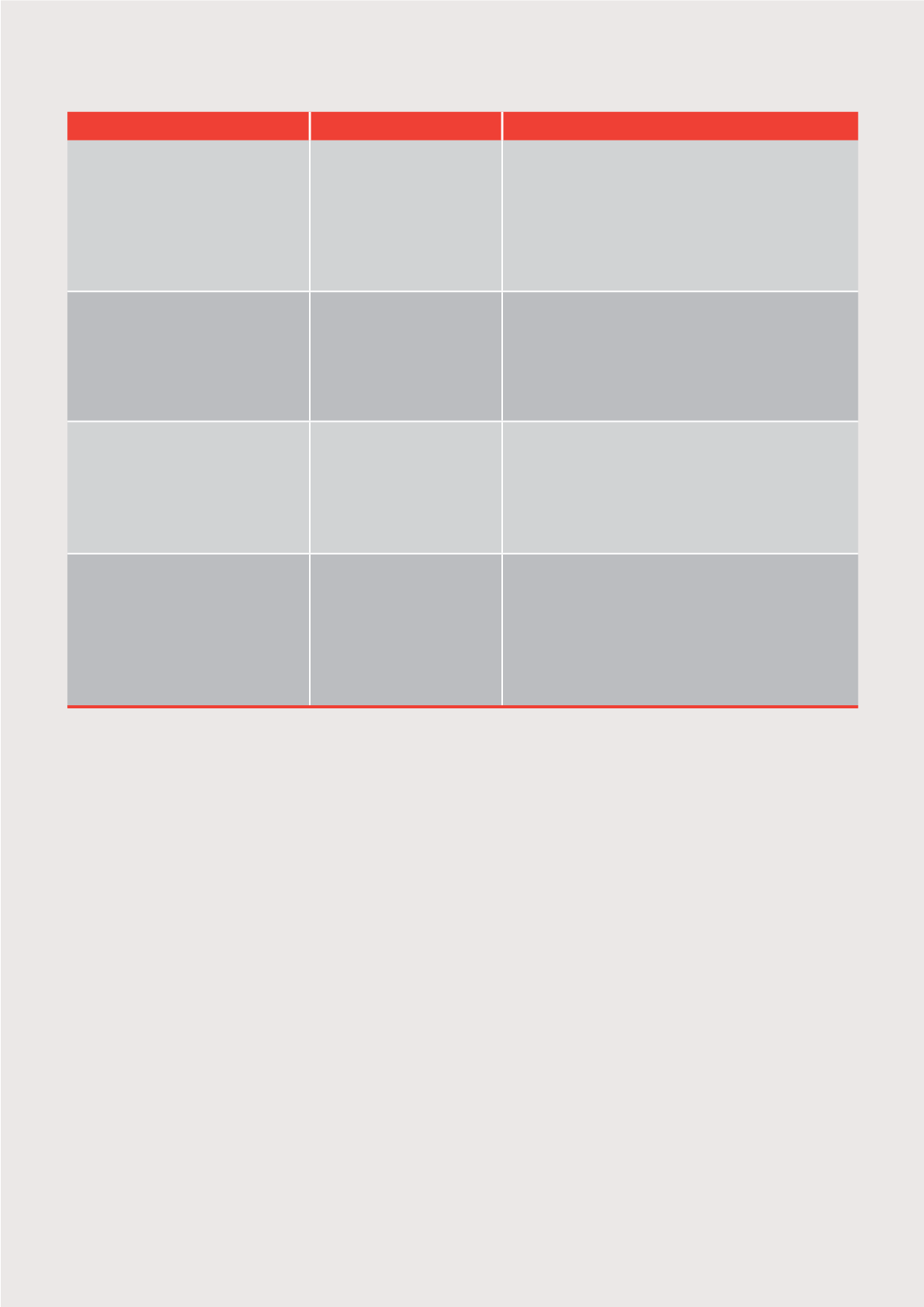

Objectives

Targets

Program

Accidents & Incident Rate,

near-miss & non-compliances

Reduction by 50%

from previous year

• EHS orientation conducted to all newly

joined employees

• Create EHS awareness through EHS promotion

• Review trend chart monthly

• Thorough investigation of all accident,

near-miss & non-compliances and share

in Management Review Meeting

Energy conservation program Reduce consumption

through improving

operating efficiency

• Introduce high bay induction lighting in

Warehouse, reduce 50% in watt

• Switching to air compressor that uses

Energy Saving Inverter Drive

• Purchase only energy saving electrical injection

molding machine whenever possible

Waste management program

• Eliminate improper

segregation & disposal

of waste

• Reduce waste by

reducing scrap, reuse

& recycling program

• Participate with customer to reduce pallet

consumption through re-use pallet

• Bring recycling awareness to office staff through

eliminating paper cup & plastic stirrer

Chemical management program Eliminate chemical spillage

resulting

in pollution

• Ensure MSDS are available & accessible through

Sharepoint

• Provide Safety First-Aid kit include Eyewash

station, Oil spill kit

• Emergency preparedness & response – to

protect people, property, the environment

& continuity of operations

are provided with key information,

i n c l u d i n g r e a l t i me r e v e n u e ,

inventory and many other important

information, via Business Intelligence

system to help them to make real

t ime dec i s i ons . Bus i ness and

operations review are conducted

monthly with top management at a

formal meeting.

Quality is a key element which the

Group is committed to. To achieve

this, the Quality Systems is reviewed

at a global level by headquarters

periodically. All plants are certified

in

ISO9001:2000

and all plants are

certified for

TS16949

or

ISO13485

if the products are automotive or

healthcare respectively.

The Europe plant was certified in

ISO13485

and target to be certified

in

TS16949

by 2Q2015. The Brazil

plant is also going for

TS16949

certification too. The Singapore plant

has also obtained

AS9100

to be

able to support the aerospace

customers in Singapore.

Following objectives & targets have set for regular review of the effectiveness of the EHS

management system